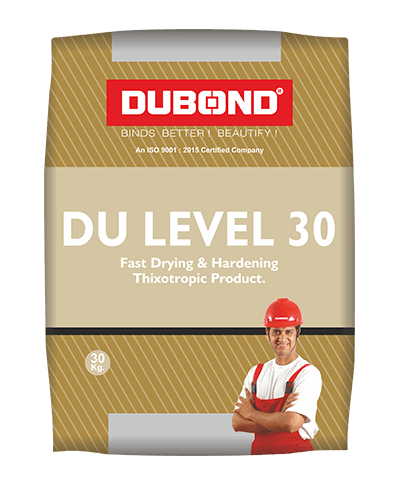

FAST DRYING & HARDENING LEVELING THIXOTROPIC PRODUCT

Dubond's DU LEVEL 30 is a thixotopic leveling product with characteristics of high pace hardening and drying, and best for irregular non planer substrates correcting up to 30 mm thicknesses on floors and walls. Its high qualities of thixotropizing polymers are resistant are resistant to an alkali environment and balance, before lying of ceramic,homogenous tiles,natural stones,parquest and resilient materials .It is a high fluid, self-leveling product of high dispersing effect (HDE) technology that creates perfectly plane substrate. The substrate has extra rapid hardening and self leveling which lives with rheological fluidity and dynamism.

Features & Benefits

Features & Benefits Area Of Application

Area Of Application Packaging

Packaging Shelf Life

Shelf Life Method of Use

Method of Use Technical Data

Technical Data